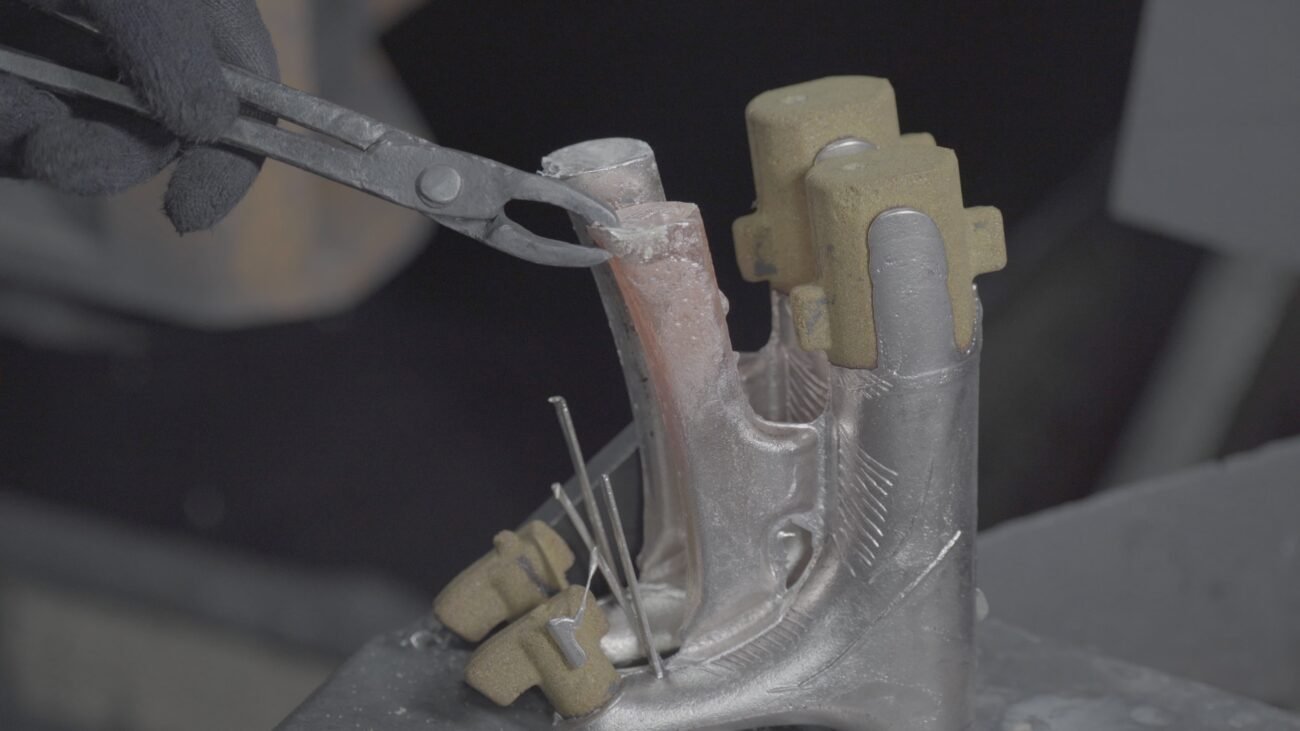

Step 1: Mold Design & Core Making

JANEDO has its own mold manufacturing capabilities to ensure that every detail is presented perfectly.

Sand core casting is the key process to ensure the precise passage inside the faucet.

We use environmentally friendly resin to make the core, which not only reduces the environmental impact,

but also ensures the precision of the casting.

The molding quality of the sand core directly affects the liquidity and durability of the faucet.

Step 2: Brass Melting

Melting

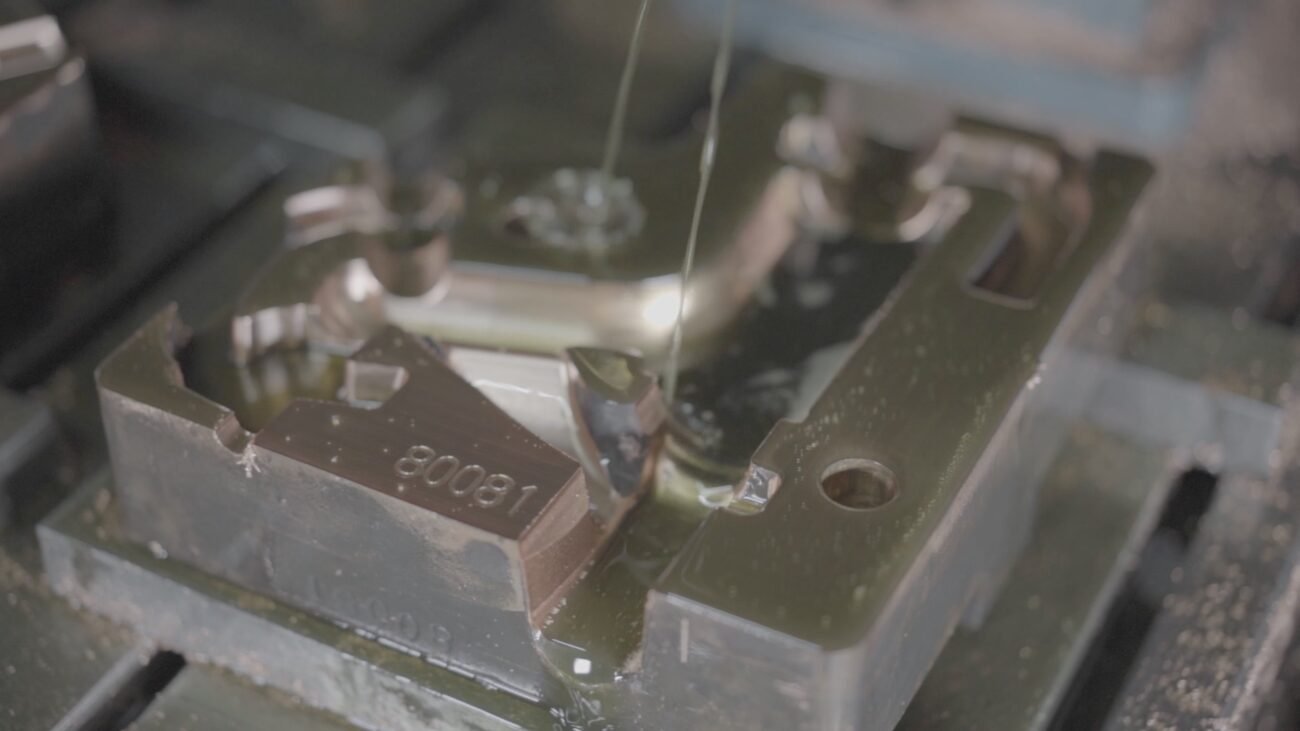

Injection mold

During the casting process, molten brass or stainless steel is injected into the mold.

JANEDO uses an Italian IMR casting machine to ensure that the castings have uniform density,

no porosity, and the material can withstand high pressure and temperature.

The blank after casting is the prototype of the faucet.

Step 3: Machining

The cast blanks are machined with CNC precision to further ensure the accuracy,

sealing and flow control of the internal channel of the faucet.

The precision of each hole position and joint will affect the performance of the final product, so machining is crucial.

Why It Matters for You — The Customer

The casting process is not merely a detailed procedure within the factory; it directly determines the following key points of the faucet:

• 🛠️ product lifespan: High-quality casting means that the copper body is dense and free of pores, less prone to cracking and leakage, and has a longer service life.

• ✨ appearance and texture: A smooth and flawless surface casting is the foundation for the aesthetic appeal and texture of electroplating in the later stage.

• 💧 performance: The precise structural dimensions make the faucet run more smoothly and stably in aspects such as the valve core and water discharge.

By choosing a source factory (such as JANEDO), what you get is not only a good product, but also:

• 🔁 Quality traceability: Every step from mold making, casting, processing, electroplating to assembly is completed in the factory.

• 🎯 Flexible customization: We can respond to customers’ special customization ideas immediately without having to convey the requirements through traders.

• 📦 no minimum order quantity + OEM support: Whether it’s a small-batch test market or a brand customization project, we can flexibly cooperate.

Choosing a manufacturer with complete casting capabilities means you have control over the long-term value of your product from the very beginning.

Conclusion – Built to Last, Cast to Impress

The casting of JANEDO is not only the starting point of manufacturing but also the first guarantee of brand quality.

We always believe that a truly excellent faucet is not only attractive in appearance, but also lies in the precision of its internal structure and the meticulousness of its manufacturing process.

From high-quality copper materials, advanced IMR gravity casting, to subsequent processing, electroplating and testing, all processes of JANEDO are completed in the factory – this is precisely the confidence that enables us to commit to quality and support MOQ-free and Oems.

Welcome to contact us for more information about our products and factory.

Email: sales@janedo-sanitary.com

WhatsApp: +8615214792801

Ahaa, its pleasant discussion concerning this piece of writing here at this website, I have read all that, so now me also commenting here.